Sustainability at FALKE 2020

Released June 2020

Mission statement

Since 1895, the FALKE family business has been standing for modern legwear made from high-quality materials, finished with handcrafted perfection and an eye for detail. A deep understanding of yarns and manufacturing techniques handed down from generation to generation and continuously refined is the basis for all our products. This also includes functional underwear, sportswear and knitwear for women, men and children.

Customers who decide upon FALKE products not only trust in FALKE's promise of quality. They also make a conscious choice in favour of a manufacturer who has always given priority to acting in a socially and environmentally conscious manner. Instead of outsourcing our production, like many others in the fashion industry did, we continued to run our own production sites. 89% of our legwear articles are manufactured in our own factories in Germany, Italy, Serbia, Slovakia and South Africa.

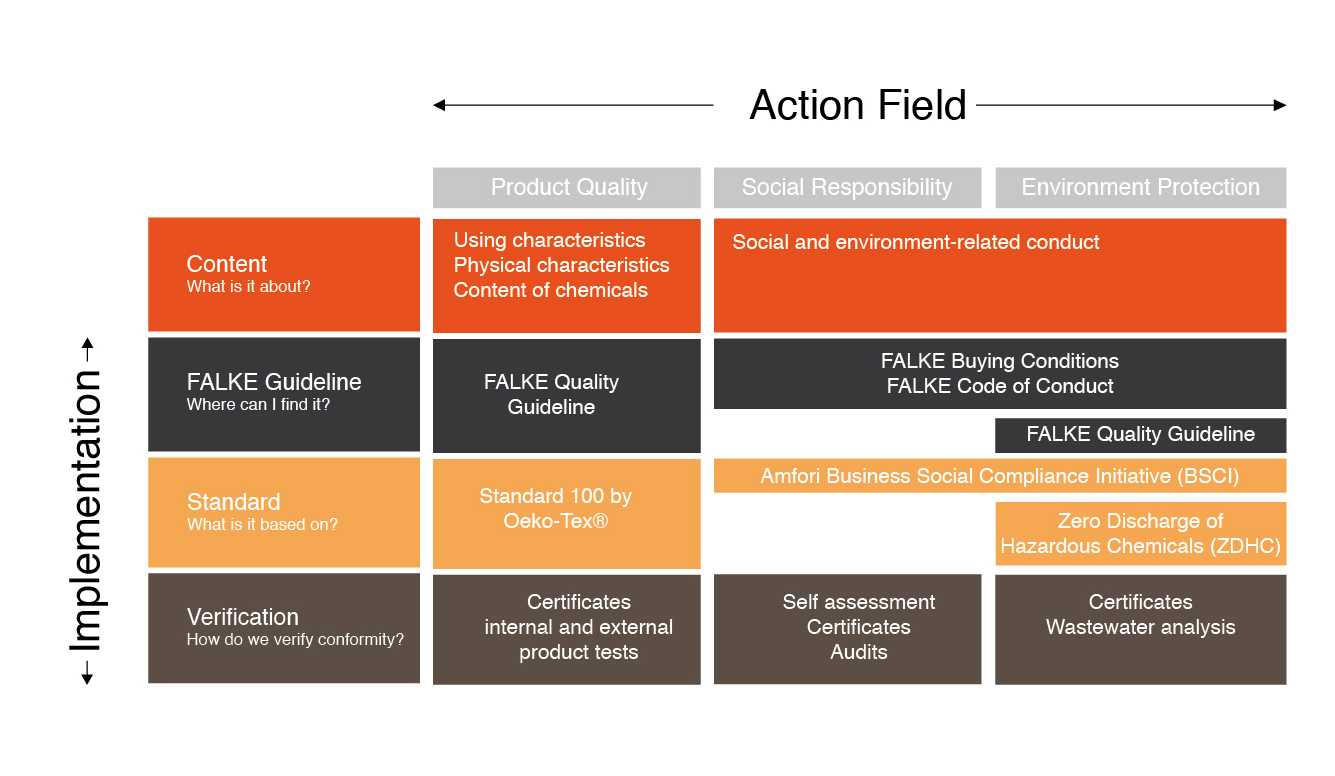

As part of our philosophy, our international business processes and operations as well as the cooperation with external partners orientate on three action fields:

Product Quality – Social Responsibility – Environment Protection

The following report will provide you with detailed information about valid guidelines and ongoing activities that support these three action fields along our supply chain. Please do not hesitate to contact us for further information.

How we make our products

The FALKE GROUP produces legwear, underwear and apparel of the brands FALKE and Burlington. Furthermore, FALKE is licensee for ESPRIT legwear.

Our drive and basic principles

Accordingly, before supplying goods to FALKE we request conformity to our guidelines from each supplier of material and finished goods.

Through our FALKE Buying Conditions and the FALKE Quality Guideline including RSL3 and MRSL4 our suppliers accept on following these guidelines and to supply the demanded goods in the quality we expect.

To verify the compliance to our requirements we assess our suppliers on a regular basis regarding working conditions, environment protection and chemical management. The audits focus on risk countries as classified by Amfori BSCI and are performed either by our specially trained employees or by independent external institutes. Based on the audit results we accompany the relevant suppliers closely to support them implementing our high standards.

To verify the compliance to our requirements we assess our suppliers on a regular basis regarding working conditions, environment protection and chemical management. The audits focus on risk countries as classified by Amfori BSCI and are performed either by our specially trained employees or by independent external institutes. Based on the audit results we accompany the relevant suppliers closely to support them implementing our high standards.

Product Quality

Physical characteristics

- Pilling

- Abrasion

- Change of colour shade

Using Characteristics

- Shrinkage after washing according to care labelling

- Visual appearance after washing

- Lose thread ends

- Colourfastness to washing

- Colourfastness to heavy water

- Colourfastness to rubbing

- Colourfastness to sweat (alkaline and acid)

- Colourfastness to saliva and perspiration

Prohibited substances

- Conformity to Restricted Substances List (RSL)

- Conformity to REACh

Meeting the FALKE Quality Guideline starts by purchasing material preferably holding an appropriate Oeko-Tex certificate. Regardless of whether a certificate is in place or not our own laboratory performs standard random incoming controls regarding the above-mentioned criteria on all materials before being processed in our facilities. The finished goods are tested during the subsequent product creation process. This applies to both, products from our own facilities and products sourced from external partners.

The tests performed in our laboratory cover the requirements of physical characteristics, using characteristics and colourfastness as figured above. Independent research and testing institutes verify compliance with the FALKE RSL, which sets the limits of certain substances that must not be exceeded in our products. The FALKE RSL considers relevant requirements of Oeko-Tex and REACh. Any exception from our guideline will be declared and results in root cause analyses with subsequent corrective actions.

Should there be any reason for complaint – we look forward to receiving your feedback for consideration in our product development and improvement process.

The tests performed in our laboratory cover the requirements of physical characteristics, using characteristics and colourfastness as figured above. Independent research and testing institutes verify compliance with the FALKE RSL, which sets the limits of certain substances that must not be exceeded in our products. The FALKE RSL considers relevant requirements of Oeko-Tex and REACh. Any exception from our guideline will be declared and results in root cause analyses with subsequent corrective actions.

Should there be any reason for complaint – we look forward to receiving your feedback for consideration in our product development and improvement process.

Social Responsibility

To be in line with our definition of social responsibility the conformity to the BSCI Code of Conduct along the supply chain is an essential part of our Buying Conditions. BSCI is an optional initiative for companies to support the improvement of working conditions along their supply chains. Specific institutes perform audits on a regular basis at participating companies around the world. FALKE is BSCI participant for years and performs audits in all own facilities in BSCI risk countries.

Independent of the availability of a valid BSCI audit we follow up the adherence to the intended social standards. Based on the supplier evaluation either our specially trained employees or independent external institutes visit the facilities on a regular basis. Assessments include but are not limited to monitor working conditions, fair wages and safety aspects. Based on audit results and development we provide close support to the factories to implement our high standards and to improve their BSCI rating. In addition to full audits FALKE continuously performs spot checks along the value chain during regular routine visits for status updates and progress monitoring.

Environment Protection

Environment Protection means to FALKE meeting nature with the biggest respect along the whole product creation process and supply chain. Right from the start, we develop our products under consideration of material origin and consequences of the required production process. We review our production and logistic processes continuously to reduce energy consumption, waste and rejects. We started to summarize our goals, activities and achievements regarding Environment Protection in the green box below. You will find updates of this box on a regular basis.

Animal Welfare

Beside prevention of pollution and carbon dioxide emission, animal welfare has been and is a matter of course for us. Wool is one of the most important raw materials we use in our products. Therefore, we have set animal protection as an essential principle in our FALKE Quality Guideline. Please find relevant guidelines and requirements for the individual kinds of wool below.

| Material | Compliance to following guideline |

| Sheep wool | IWTO Guideline for sheep welfare and Mulesing free |

| Angora | Certified by CaregoraTM |

Mulesing is a painful treatment of sheeps to avoid infestation of special maggots. The FALKE Quality Guideline forbids the use of this method to grow wool. According to current planning figures5 compliance to our guidelines for animal welfare and requirements for the individual kinds of wool can be proved for more than 99,1% of the wool purchased in 2020. For < 0,9% of the wool we have no proof it has been won mulesing-free. In the meantime, new contracts have been concluded with our suppliers. Since April 2020, all guidelines and requirements for the purchase of wool are 100% fulfilled.

Zero Discharge of Hazardous Chemicals (ZDHC)

In textile production the main concern is the exhaust of wastewater from chemical processes. These so called “wet processes” are used for dying as well as for treatment of materials to achieve certain functional or haptic product characteristics. We continuously work on innovative processes to reduce the usage of chemicals within our processes – no matter if this concerns our own or external factories. All chemicals used for the production of our products meet the statutory REACh standards of the European Union.

As a proof of conformance, we perform wastewater analyses on all our own factories with “wet processes” and request valid analyses from suppliers with wet processes. In case of non-conformance we agree on countermeasures. The analyses base on ZDHC criteria, a global initiative of fashion brands targeting to bring harmful substances within the manufacturing process to zero.

As a proof of conformance, we perform wastewater analyses on all our own factories with “wet processes” and request valid analyses from suppliers with wet processes. In case of non-conformance we agree on countermeasures. The analyses base on ZDHC criteria, a global initiative of fashion brands targeting to bring harmful substances within the manufacturing process to zero.

|