Sustainability at FALKE 2022

Mission statement

Dear Readers,

Through our regular Sustainability Report, we would like to share with you our understanding, our views and our goals about sustainability.

Sustainable corporate governance has always accompanied us and is reflected in our corporate culture, our processes and even in the design of our products. We countered the challenges that increased in 2022 with the ongoing Corona pandemic and the Ukraine conflict by taking appropriate measures along our supply chain without contradicting our values and corporate responsibility. Once again, it has been demonstrated that our adherence to our own production sites and the close partnership with our suppliers form the basis for our long-term existence and the lasting success of our company.

The sustainability principles "social, ecological and economic" are considered throughout the company in the daily activities of our employees. The corporate and product sustainability initiatives launched in 2021 are showing exciting results.

We are replacing an increasing number of conventional materials with sustainable alternatives, so that the proportion of sustainable products that we carry under the "WE CARE" label is growing steadily. Since 2021, we now record our carbon footprint annually and initiate appropriate measures to avoid and reduce emissions, ranging from switching to green electricity to considering solutions for using renewable energy at our own sites. Continuously scrutinizing our processes is likewise part of this.

We hope you enjoy reading the report. Please do not hesitate to contact us for further information or feedback.

Best regards,

Franz-Peter Falke Paul Falke

How we make our products

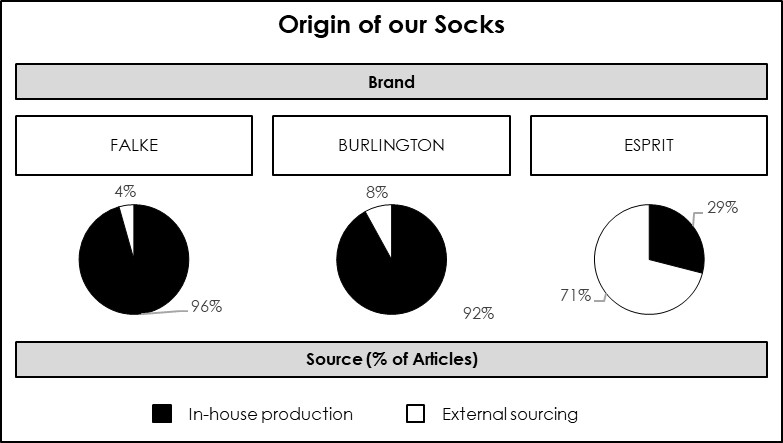

The FALKE GROUP produces legwear, apparel and underwear of the brands FALKE and Burlington. Furthermore, FALKE is licensee for ESPRIT legwear.

Our drive and basic principles

Our business operations are determined by the action fields Product Quality, Social Responsibility and Environment Protection. Corresponding guidelines set the framework of thinking and acting for us and for our suppliers. These guidelines base on internationally accepted standards as OEKO-TEX® Standard 100, the amfori BSCI[1] Code of Conduct and the ZDHC[2] initiative. The relevant Standards will be described further in the following sections.

Through our FALKE Buying Conditions and the FALKE Quality Guideline including RSL[3] and MRSL[4] our suppliers accept on following these guidelines and to supply the demanded goods in the quality we expect – for more information, please find the documents at the end of the report.

To verify the compliance to our requirements we assess our suppliers on a regular basis regarding working conditions, environment protection and chemical management. The audits focus on risk countries as classified by amfori BSCI and are performed either by our specially trained employees or by independent external institutes. Based on the audit results we accompany the relevant suppliers closely to support them implementing our high standards.

Product Quality

We design and develop our products to be in line with the FALKE quality requirements. OEKO-TEX® Standard 100 is the basis for the FALKE Quality Guideline which is provided to our material suppliers, our own production facilities as well as external manufacturers of finished goods. According to the OEKO-TEX® Standard 100, textiles are tested for harmful substances beyond legal requirements. We assess quality along four categories:Physical characteristics

Pilling

Abrasion resistance

Change of colour shade

Using Characteristics

Shrinkage after washing according to care labelling

Visual appearance after washing

Lose thread ends

Colourfastness

Colourfastness to washing

Colourfastness to heavy water

Colourfastness to rubbing

Colourfastness to sweat (alkaline and acid)

Colourfastness to saliva and perspiration

Prohibited substances

Conformity to Restricted Substances List (RSL)

Conformity to the EU Regulation REACh[5]

Meeting the FALKE Quality Guideline starts by purchasing material preferably holding an appropriate OEKO-TEX®-Standard-100 certificate. Regardless of whether a certificate is in place or not our own laboratory performs standard random incoming controls regarding the above-mentioned criteria on all materials before being processed in our facilities. The finished goods are tested during the subsequent product creation process. This applies to both, products from our own facilities and products sourced from external partners.

The tests performed in our laboratory cover the requirements of physical characteristics, using characteristics and colourfastness as figured above. Independent research and testing institutes verify compliance with the FALKE RSL, which sets the limits of certain substances that must not be exceeded in our products. The FALKE RSL considers relevant requirements of OEKO-TEX® Standard 100 and REACh. The REACh regulation includes an assessment of the risks of substances for humans and the environment and limits or excludes their use in textiles. Any exception from our guideline will be declared and results in root cause analyses with subsequent corrective actions.

FALKE has been certified according to OEKO-TEX® Standard 100 for many years. This standard proves the conformity of our products with the corresponding requirements for physical and chemical product properties. In addition, we have been certified according to the Organic Content Standard (OCS) and the Recycled Claim Standard (RCS) since 2021. These certificates provide us with the opportunity to ensure appropriate traceability for organically grown and recycled materials. This is done considering the entire supply chain, which must also be certified. Further information on the standards can be found on the websites of the standard providers:

OEKO-TEX® Standard 100: https://www.oeko-tex.com/

OCS: https://textileexchange.org/standards/organic-content-standard/

RCS: https://textileexchange.org/standards/recycled-claim-standard-global-recycled-standard/

Should there be any reason for complaint – we look forward to receiving your feedback for consideration in our product development and improvement process.

Social Responsibility

To be in line with our definition of social responsibility the conformity to the BSCI Code of Conduct along the supply chain is an essential part. Therefore, this is anchored in our Buying Conditions. BSCI is an optional initiative for companies to ensure and support the improvement of working conditions along their supply chains. Specific institutes perform audits on a regular basis at participating companies around the world. FALKE is BSCI participant for years and performs audits in all own facilities in BSCI risk countries. FALKE also accepts adequate social standards as an alternative.Environment Protection

Environment Protection means to FALKE meeting nature with the biggest respect along the whole product creation process and supply chain. Right from the start, we develop our products under consideration of material origin and consequences of the required production process. We review our production and logistic processes continuously to reduce energy consumption, waste and rejects. We have summarised further information under "Goals, measures and successes in environmental protection" and update this regularly.

Animal Welfare

Animal Welfare has been and is a matter of course for us. As wool is one of the most important raw materials we use in our products, we havae set animal protection as an essential principle in our FALKE Quality Guideline. Please find relevant guidelines and requirements for the individual kinds of wool below.

| Material | Compliance with following guideline |

| Sheep’s wool | IWTO Guideline for sheep welfare Mulesing free |

| Angora | Certified by Caregora™ |

Mulesing is a painful treatment of sheeps to prevent infestation of special maggots. Our Quality Guideline excludes the purchase of wool obtained using this method.

Hazardous Substances & Chemical Management

In textile production the main concern is the exhaust of wastewater from chemical processes. These so called “wet processes” are used for dying as well as for treatment of materials to achieve certain functional or haptic product characteristics. We continuously work on innovative processes to reduce the usage of chemicals within our processes – no matter if this concerns our own or external factories. All chemicals used for the production of our products meet the statutory REACh standards of the European Union.

As proof of conformance to the ZDHC criteria, a global initiative of fashion brands aiming to reduce harmful substances within the manufacturing process to zero, we perform wastewater analyses for all our factories with wet processes. For external factories with wet processes, we request a valid wastewater analysis and agree on measures in case of deviations from the standard.

Climate Protection

We are aware of our responsibility towards the global climate and the environment, and we therefore strive to minimize our greenhouse gas emissions. We have been measuring our carbon footprint in accordance with the Greenhouse Gas Protocol since 2021 and using the result to define short-, medium- and long-term measures to avoid and reduce our emissions. The results as well as the main sources of the corresponding emissions are communicated to the entire FALKE team and are in focus of our activities. The implementation of measures is planned and followed up within our sustainability team.

FALKE - WE CARE

In addition to fulfilling existing requirements in the areas of social responsibility and environmental protection, we strive to continuously improve and intensify sustainable business practices at FALKE within the corporate initiative FALKE - WE CARE.

FALKE – WE CARE - Label for sustainable material

With our label WE CARE, we identify products that are made from sustainable materials. Beyond the requirements of the valid FALKE Quality Guideline and Purchasing Guideline, sustainability in this context is measured by the criteria resource-efficient, socially responsible and traceable.

Resource-efficient

We use materials that are grown or produced with reduced resource consumption. This can be represented by recycling, effective irrigation systems, short transport routes or the use of regenerative energy sources.

In the supply chain, we demand the improvement of working conditions, the payment of fair wages and the observance of safety aspects and ensure this through appropriate evidence.

Traceable

We strive for the highest possible transparency in the traceability of the materials we use, preferably by requesting the relevant certificates. We work together with long-standing business partners in the procurement of materials and inform ourselves very precisely about the origin of the materials.

FALKE – WE CARE – Protection of species

Our responsibility towards the environment, employees and society is an integral part of "FALKE - WE CARE". Together with our employees, we are involved in a project to actively support local species conservation. The family-owned company FALKE is located in the heart of the Sauerland region at its founding site in Schmallenberg. In the midst of nature, surrounded by forests and meadows, an appropriate commitment lends itself. On free areas of the company's property, the project team has settled bee colonies, whose honey was recently sold for a good cause. The pollination by the bees within a radius of up to 3 km around the settlement area contributes significantly to the preservation of the vegetation and wildlife. Besides the positive effects on the environment, the project offers all employees variety in their daily work and promotes cohesion and interaction among colleagues.

|

[1] amfori Business Social Compliance Initiative

[2] Zero Discharge of Hazardous Chemicals

[3] Restricted Substances List (guideline for substances in the product)

[4] Manufacturing Restricted Substances List (guideline for substances used in the manufacturing process)

[5] Registration, Evaluation, Authorisation and Restriction of Chemicals